Product Description

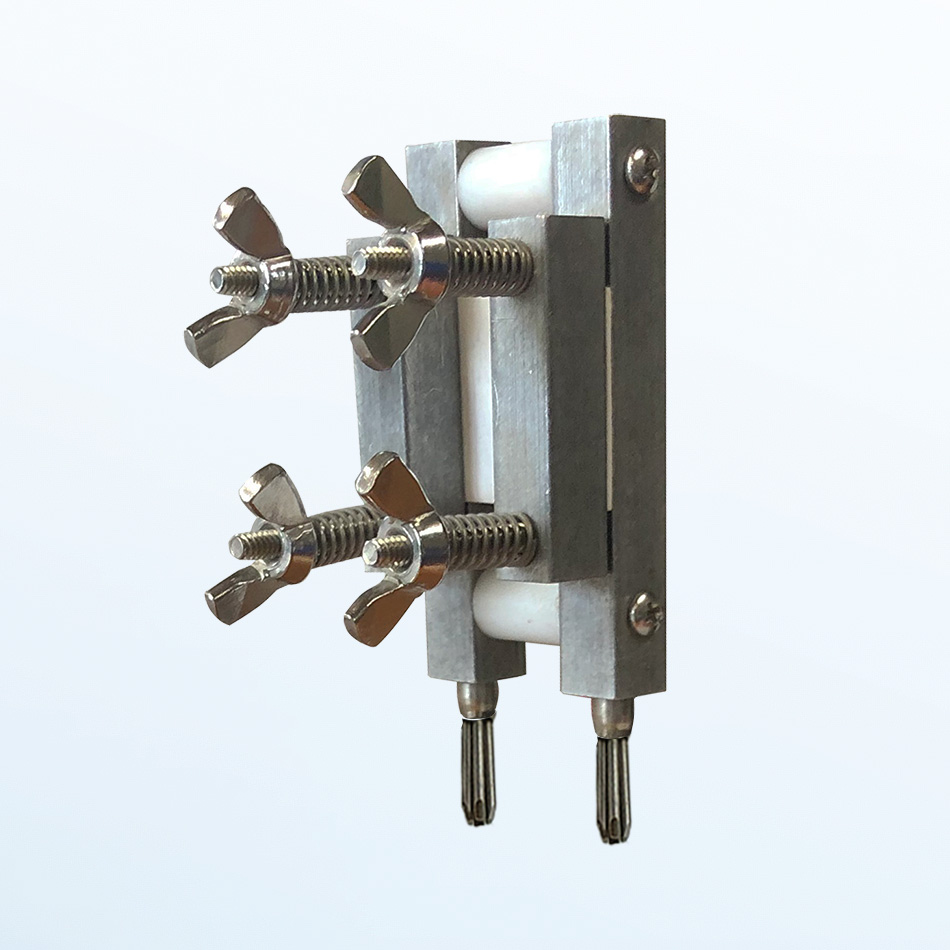

The EMC holder is used to measure the moisture content of a cellulose wafer. After a quick acclimation, the moisture content of the wafer is the same as the Equilibrium Moisture Content (EMC) of the surrounding air.

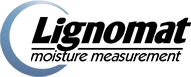

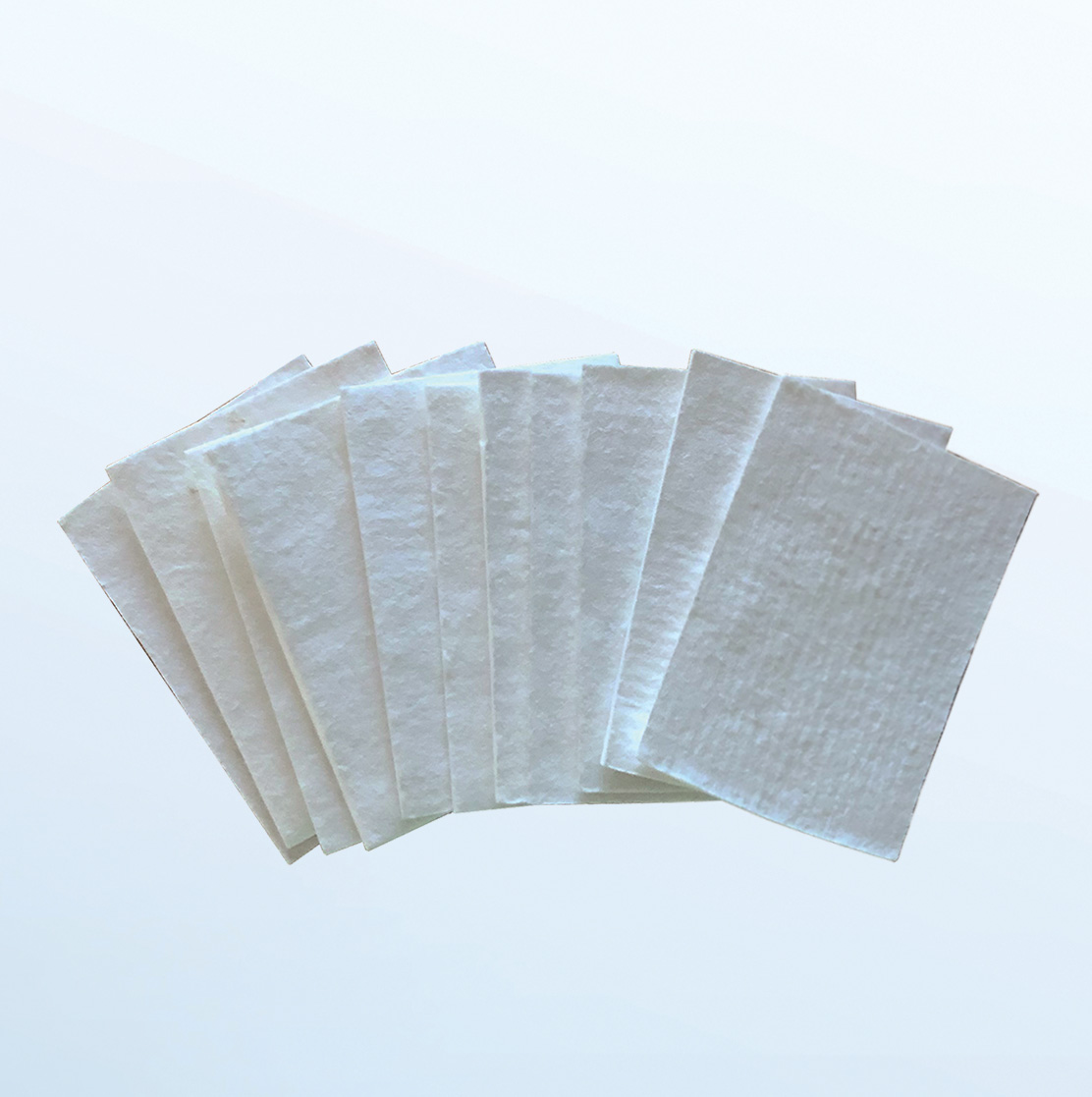

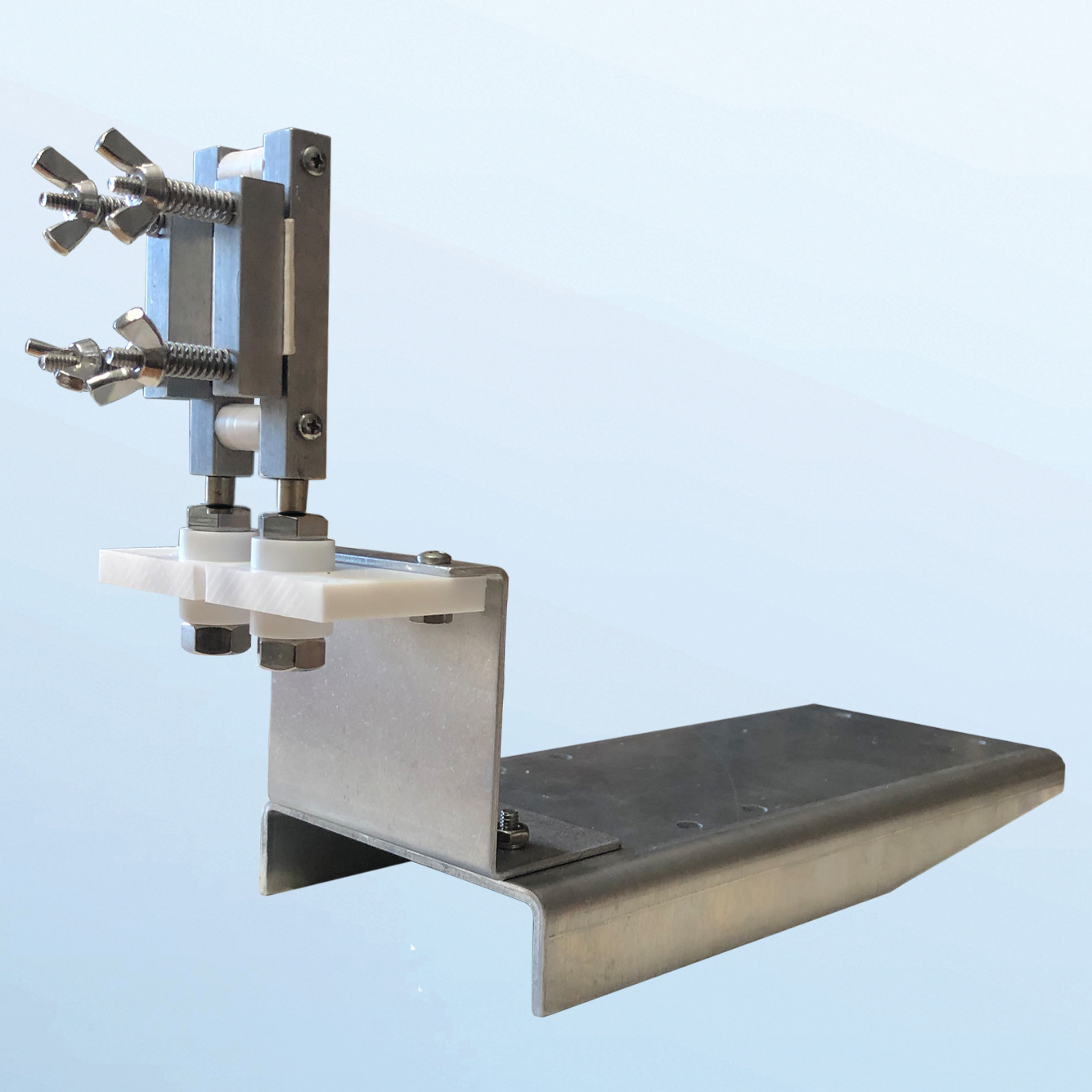

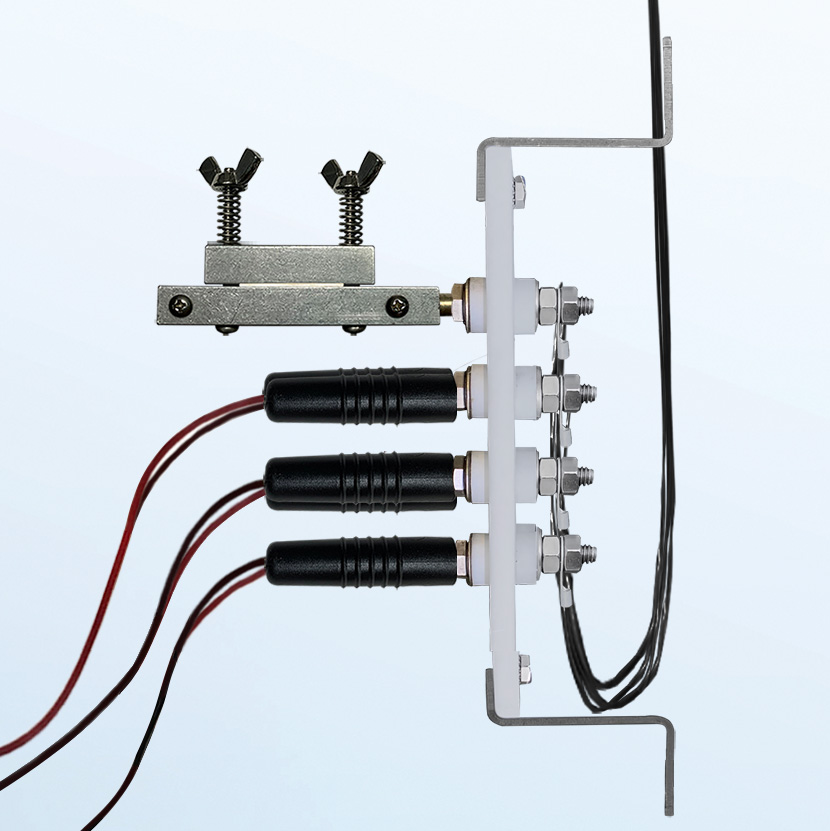

The EMC holder is equipped with two sets of measuring plates, which are pressed together by spring loaded wing bolts. The wafer is placed between the plates. To make the electrical connection, the EMC holder is plugged into an angle connector. From there a PK-H cable makes the connection to a moisture meter or the measuring box for the kiln contol system.

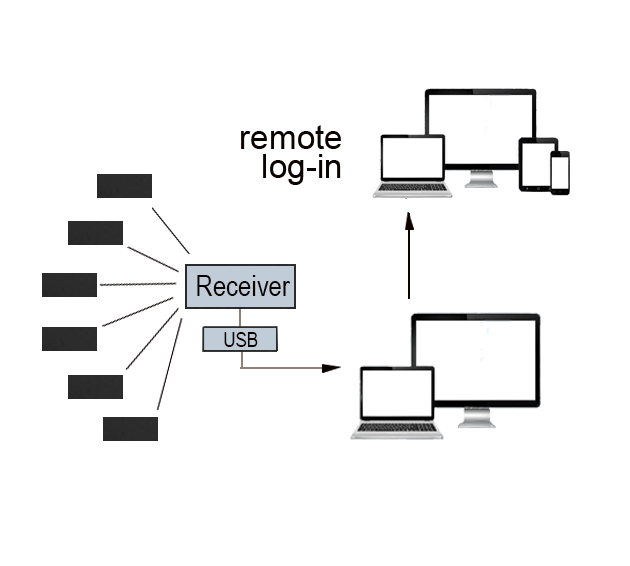

In-kiln cables can be avoided with the wireless monitoring system for dry kilns.

One of the main applications is measuring EMC inside a dry kiln. EMC holder, angle connector and mobile station are made from aluminum, stainless steel and teflon to withstand the corrosive air and hot temperatures inside a drying chamber.

Using EMC wafers in dry kilns to measure humidity is an excellent choice. The cellulose EMC wafer is inexpensive, reliable and not affected by the corrosive air nor by high temperatures inside lumber dry kilns. Measuring elements in relative humidity probes and thermo-hygrometers will likely be destroyed within a few months by the corrosive air in a dry kiln. Wet-bulb dry bulb thermometer stations are cumbersome to maintain. Lignomat has used EMC measurements with cellulose wafers in lumber dryers and pre-dryers for over 50 years.

Measuring EMC: The cellulose wafer quickly reaches an equilibrium with the surrounding air wherever it is placed, inside a dry kiln, air drying shed, warehouse, shop, house or office. To obtain EMC measurements, connect the Ligno-VersaTec or the Lignometer K, select the EMC setting and the correct temperature and the meter indicates the EMC value for the relative humidity and temperature of the surrounding air. The kiln control systems and wireless monitors automatically correct for the EMC setting and the temperature and produce corrected EMC values.

EMC Charts:

Corresponding values for stable conditions of relative humidity / temperature and wood moisture content

— EMC-Chart up to 120°F (50°C)

— EMC-RH-WB Chart for kiln-dyring up to 210°F (100 °C)

— EMC-RH-WB Graph for kiln-drying up to 260°F

— EMC-RH-WB Graph for kiln-drying up to 120°C

Charts can also be used as conversion from EMC values to relative humidity percentages and wet-bulb-dry-bulb temperatures,

Example:

At a temperature of 70°F and 45% relative humidity, the EMC according to the chart is 8.5 %. That means, wood with a moisture content of 8.5% is stable, it will not absorb or loose any moisture, will not shrink, warp or cup. If wood in the same ambient conditions has a moisture content of 10.5%, it will loose moisture until 8.5% has been reached. This loss in moisture can cause wood movement depending on wood species, wood thickness and time of exposure.

Looking at drying conditions in dry kilns or wood sheds: If the moisture content of wood is 15% and the EMC of the surrounding air independent of the temperature is also 15% no drying will take place. If the moisture content of the wood would be 22%, there is a moisture gradient and the wood will dry. Lignomat has been using EMC measurements from cellulose wafers for over 50 years to control the drying process in kiln control systems.

Equipment:

— EMC wafer

— EMC Holder

— Angle connector

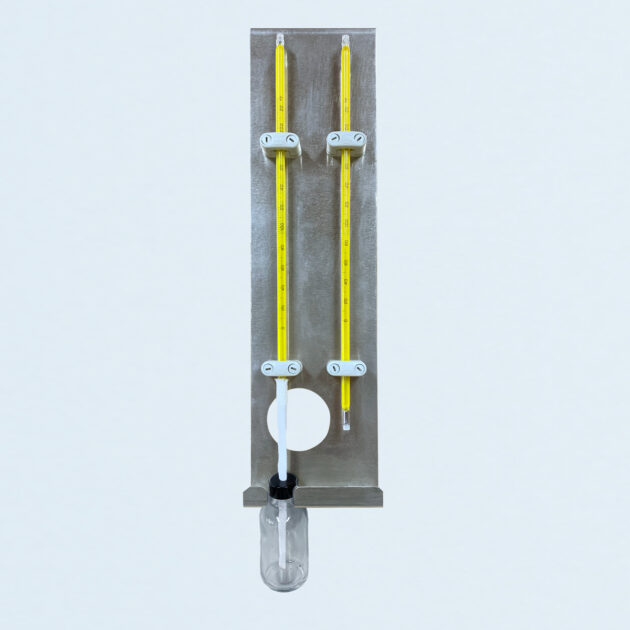

— EMC mobile mount: EMC holder with plate to slide into stacked lumber

— PK-H cable to plug into angle connector, measuring station and mobile mount.

Measurements:

— Ligno-VersaTec

— Lignometer K

— MC Tracker

— Wireless monitor

— Kiln control systems

mini-Ligno DX/C can be used, but the resolution (1%) above 10% EMC may not be enough. The moisture meters Lignometer K and the Ligno-VersaTec indicate moisture with a 0.1% resolution for the entire range.

For more information please contact Customer Service at 1-800-227-2105.

Lignomat USA Ltd, 14345 NE Morris Ct., Portland OR 97230, USA,

Email: sales@Lignomat.com, www.Lignomat.com