Product Description

Package K2-10M

The K2-10M package includes the cable/pin system allows monitoring for moisture changes in hard-to-reach, inaccessible areas, during drying-out after water damage and for long-term leak surveillance. Additionally for in-depth measurements, the E12 electrode is used to determine if a moisture gradient exists between surface and core. True moisture levels can be detected up to 2″ deep, even behind wet surfaces.

The package K2-10M consists of:

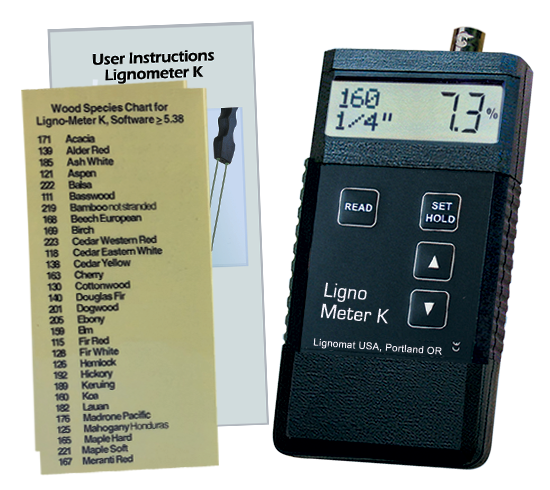

- Lignometer K moisture meter

- Electrode E12 with 1 pair each DA and DZ pins

- BNC cable

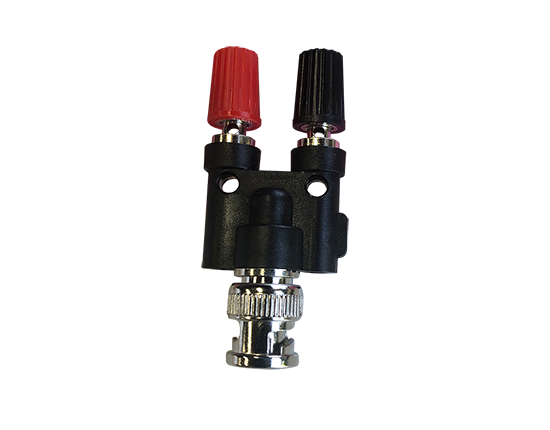

- 1 adapter H

- 1 set of screws with washers

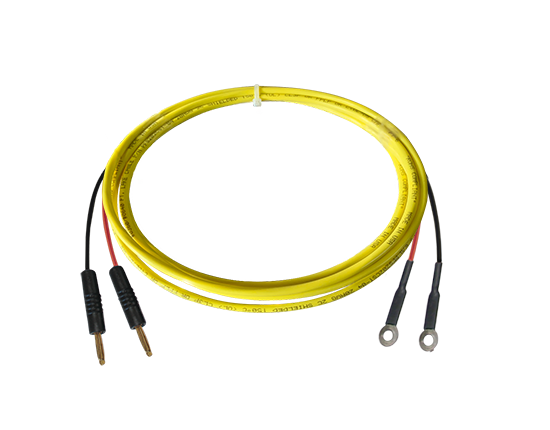

- 1 cable (Loop-H)

- Case M

- optional set of cables 1, 3 or 5

The Lignometer K incorporates the most advanced measuring technology for pin moisture meters with over 125 individual wood species corrections, a wide measuring range 5-99% and built-in wood temperature corrections. Reliability, calibration accuracy and ease-of-operation are outstanding. Unsurpassed accuracy is guaranteed even in the critical range below 8%. The Lignometer K has proven to perform well in rough mill environments with day-to-day usage.

Easiest monitoring of moisture problem areas

Cables and pins work well for monitoring areas in buildings, which are prone to moisture problems or have already had a moisture problem. Leaky roofs, wet crawl spaces, faulty installed windows, broken pipes, cracked waterline behind a refrigerator can be a cause for moisture problems. Unnoticed moisture infiltration can have severe consequences, floors are ruined, dry rot develops and structural components disintegrate. Cables should be installed while the area is still under construction or under repair, because after the walls are closed up, the areas are often inaccessible.

Pins/cables can be used for short-term or long-term monitoring. When taking multiple measurements a series of truly comparable values will be produced, because all measurements come from the same spot at the same measuring depth. Measurements are done quickly by connecting the open cable end to the meter.

This is an easy way to monitor, if the drying-out process during water damage repair work is proceeding as expected. It also allows leak surveillance to make sure, that a problem does not occur or does not re-occur after repairs are completed. Measured values will indicate any change in moisture content. See photo, the same spot can be measured repeatedly to determine, when the material is dry enough to close-up the wall.

This is an easy way to monitor, if the drying-out process during water damage repair work is proceeding as expected. It also allows leak surveillance to make sure, that a problem does not occur or does not re-occur after repairs are completed. Measured values will indicate any change in moisture content. See photo, the same spot can be measured repeatedly to determine, when the material is dry enough to close-up the wall.

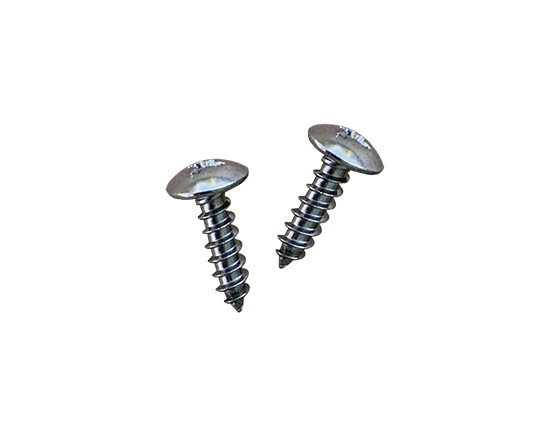

Pins (screws) are installed in the trouble spot and connected to a LP-H cable. When using screws the meter indicates the highest moisture value in the area between the screws, could be the surface or the inside. Screws measure the wettest spot. Teflon-coated pins only measure at the tip, they will indicate a dry inside even if the surface is wet. Cables should be ordered long enough to keep the open cable-end in an easily accessible area. Measurements are taken by plugging the open cable-end into the meter. If cables are already installed to monitor the drying-out process, they could be left in place for long-term monitoring.

An assortment of pins is available:

– off-the-shelf, stainless steel screws 1/2″

– EG pins, teflon-coated 3/4″

– EL pins, teflon-coated 7″

Hardware to connect screws/pins to Lp-H-cables is included

The Lp-H cable connects the meter to all pins listed above. The cables in the K2-10M package have a standard length of 3 ft. Cables can be ordered in sets of 1, 3, 5. Longer cables are available upon request.

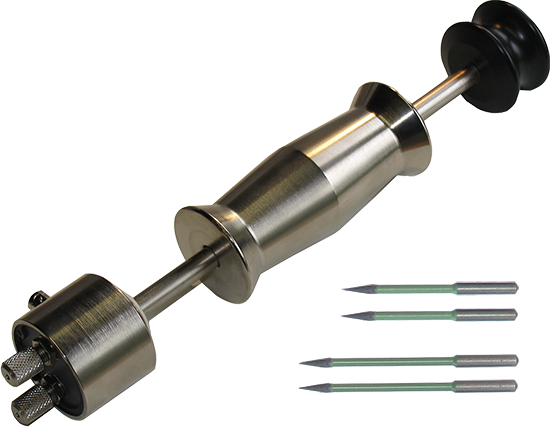

Depth Measurements with Electrode E12:

The ability to measure a moisture gradient is one of the main reasons for our customers to use the E12. Moisture problems can be avoided when the wood has been confirmed to be dry throughout the core. For restoration applications, the electrode E12 can find moisture within the building structure, even behind wall coverings. Hardwood floors can be measured through the floor planks.

Electrode E12: The E12 is designed to measure from the surface to 2″ deep (with DB pins). All E12 pins are insulated and measure only at the tip. The slide hammer helps inserting and removing the pins.  As pins are hammered into the material, consecutive readings show the moisture distribution within the material at every depth level the pins are driven to. The ability to measure a moisture gradient is one of the main reasons for our customers to use the electrode E12. No other tool can achieve the same measuring accuracy at a defined depth.

As pins are hammered into the material, consecutive readings show the moisture distribution within the material at every depth level the pins are driven to. The ability to measure a moisture gradient is one of the main reasons for our customers to use the electrode E12. No other tool can achieve the same measuring accuracy at a defined depth.

Wood: Taking numerous readings as pins are inserted, indicate if a moisture gradient exists or if the wood is dry throughout the core. Making sure wood is evenly dried is the best assurance for quality wood products. The thicker the wood, the more important core readings become. When inspecting wood floors, using the E12 gives you a tool to assess moisture distribution through floor planks into the sub floor without having to remove any floor planks. No other tool can achieve the same measuring accuracy at a defined depth.

Restoration: The moisture in structural components even behind wall coverings can be checked with the electrode E12. When assessing water damage, the pins of the E12 can be driven to different depth levels and thus indicate how far water has been absorbed or if there is still residual moisture inside the structure after drying. Insulated pins can measure dry material behind wet surfaces.

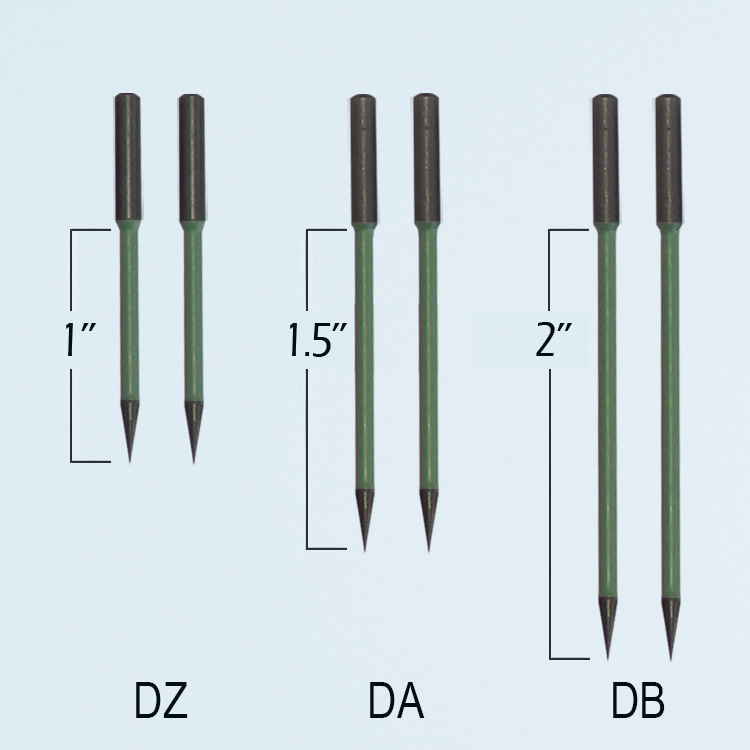

The electrode E12 comes with 1 pair each of 1″ pins and 1 pair of 1.5″. The 2″ long pins need to be ordered separately.

E12 pins are teflon coated to only measure at the tip and come in three sizes:

– DZ Pins insulated, measuring depth 1”

– DA Pins insulated, measuring depth 1.5”

– DB Pins insulated, measuring depth 2” (order separately)

For more information please contact Customer Service at 1-800-227-2105.

Lignomat USA Ltd, 14345 NE Morris Crt., Portland OR 97230, USA,

Email: sales@Lignomat.com, www.Lignomat.com