Why the In-situ Probe Test is important

Concrete slabs are an integral part of a building. Excess moisture in a slab will over time be released and can affect the entire building including in particular floor coverings. The ASTM F2170 in-situ probe test was created to accurately measure the moisture that would be released once a floor covering was put on top of a concrete slab.

Concrete slabs are an integral part of a building. Excess moisture in a slab will over time be released and can affect the entire building including in particular floor coverings. The ASTM F2170 in-situ probe test was created to accurately measure the moisture that would be released once a floor covering was put on top of a concrete slab.

Moisture testing in concrete is conducted to determine, whether or not floor coverings, sealers or epoxies can be applied without future problems. The question is, how can we predict what happens in a slab once the floor covering has been installed. See graph 1 and 2 showing the difference in moisture distribution between an uncovered and a covered slab.

It has been determined by the experts, that the moisture content is the same at 40% depth in a slab on grade, whether the slab is covered or not.

Therefore, 40% measuring depth delivers the most reliable results.

A slab is considered dry:

- When most free water is bound.

- An equilibrium with the surrounding air has been reached.

- No other moisture source (e.g., ground water) is available.

Concrete is a hygroscopic material, it absorbs water like a sponge.

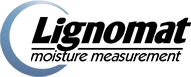

Graph 1: Moisture Distribution in an uncovered Slab As long as the slab is drying, it loses moisture through the surface. The drier surface will continuously pull moisture from the bottom up to evaporate through the surface. Until the slab is totally dry, the bottom will have a higher moisture content than the top of the slab, unless moisture is added from the top (water spill).

|

|

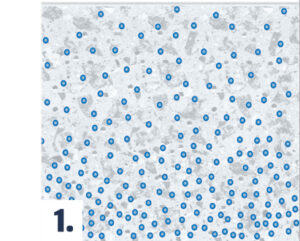

Graph 2: Moisture Distribution with Floor Covering If the moisture distribution in an uncovered slab is as shown in graph 1, then, once the surface is covered and sealed, all moisture inside the slab is trapped and will slowly distribute itself evenly throughout the slab. The result will be less moisture at the bottom and more moisture towards the top. The increase in moisture at the top of the slab could damage the floor covering.

|

|

|

The in-situ moisture test in concrete is performed to determine whether or not floor coverings can be installed, ASTM F2170. It has been found, that at 40% slab thickness the moisture distribution is the same, in a covered or uncovered slab. For slabs not on grade this is at 20% slab thickness. For that reason, the most reliable RH probe testing in covered and uncovered slabs is conducted by measuring moisture at 40% (20%) depth.

|

|

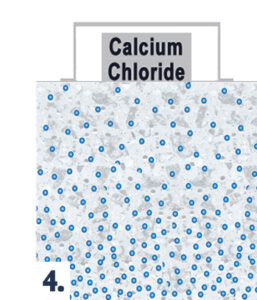

Graph 4: Calcium Chloride Test KitThe Calcium Chloride test measures the evaporation of moisture from the surface of the slab. The moisture is absorbed by the Calcium Chloride and the increase of weight is measured. The test does not take into consideration moisture in the middle or the bottom of the slab. Also, the evaporation which is measured by the Calcium Chloride test, depends on the ambient humidity around the slab. On a dry day with low relative humidity, a wet floor evaporates more moisture than on a humid day!

|

|

Graph 5: Pinless Moisture Meters Pinless moisture meters measure 3/4″ at the most 1″ deep. They indicate the average moisture within the measuring field. ASTM standard F2659 states, that handheld moisture meters can be used to compare moisture levels, but do not produce absolute moisture values. Pinless moisture meters measure moisture close to the surface. When comparing different measurements, they will show areas of high and low moisture. A pinless moisture meter can be very helpful, when selecting the areas where the in-situ probe test (3) should be placed.

|

|

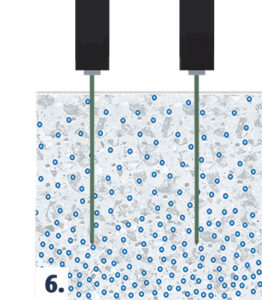

Graph 6: Pin Moisture Meters Pin moisture meters with teflon-coated pins can measure moisture up to 7″ deep (EL pins). The value the moisture meter indicates is not a percent moisture value. Different chemicals added to the concrete affect the measured values and therefore a reliable calibration, which would work for all concrete slabs cannot be found. However, measurements with EL pins from the same slab at different depth levels give comparable values and show, how much of a moisture gradient exists within the slab. |

|

The safest course of action for the floor installer is to check the installation manual from the floor, adhesive and epoxy manufacturers. The installation guidelines usually contain what kind of concrete moisture test is required and what moisture range is permissible to install floor coverings. Following those guidelines will guarantee the manufacturer’s warranty.

Another application for checking concrete moisture with handheld moisture meters is to check moisture infiltration into a concrete slab, when the concrete was exposed to moisture coming from the surface downwards by a broken pipe or floods. This is an application where handheld moisture meters especially pinless moisture meters can be very helpful.

All three methods to measure moisture in concrete have their own merits. The choice depends on the job on hand. If you need assistance in choosing the right equipment, call Customer Service at 800-227-2105.

→ Click here for more info on concrete meters.

→ Click here for more info on Lignomat’s RH in-situ probes.