One of our local customers brought a wide-plank engineered floor. Some of the floor planks were cupped, while other pieces had hairline cracks. We used a dual depth meter to obtain moisture measurements. The cupped pieces were measured at the 1/4″ depth setting and the wood group setting of the hardwood wear layer. The moisture values were between 7-8%, which corresponds to ambient conditions of about 40% humidity at 70°F. Luckily some packages were left over from the original deliver. Those floor planks were also measured at the same depth and species settings. All measurements were over 11%. The cupping and checking of the floor occurred – as the floor lost moisture to the surrounding air, which had an EMC of 7%. You may wonder how a stable engineered floor exposed such deformations?

First, wide planks are always more susceptible to deformation when the moisture content of the wood changes. Next, the inner core of engineered floors is generally very stable. The core-layered veneer reduces shrinking and expanding to a minimum. However, that does not include the wear layer, which will shrink and warp as any solid piece of wood of the same thickness. Being glued to the stable inner core helps, but if the dimensional changes in the wear layer are too great, then the floor will show cupping and checking.

It’s important to check the moisture content of engineered floors, when the floor is delivered, after acclimation and after the floor is installed for the final report.

As the floor planks dried about, the wear layer shrunk more than the stable core and caused the defects. Instead of helping, the wide width of the planks increased the damage. It’s important to check the moisture content of engineered floors when the floor is delivered, after acclimation and after the floor is installed for the final report.

Start the installation process correctly by checking the floor’s moisture upon delivery.

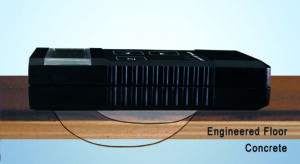

Measuring the moisture of engineered floors with a pinless moisture meter, presents a challenge because the floor is often less than 3/4″ thick and consists of different wood species (the hardwood wear layer and the birch, pine or MDF inner core). Standard pinless moisture meters are calibrated to measure 3/4″ deep. The moisture meters work very well for solid wood; however, the thickness of the wood should be at least 3/4″. Then the moisture meter can be set for the correct wood species with the measured wood being thick enough, so the entire measuring field is inside the measured piece. If less material is underneath the measuring plate, then the readings will be too low, or the material underneath will be included in the indicated moisture value.

The above photo shows a measuring depth of meter 1/4: and 3/4″. The 1/4″ depth setting is ideal for floors less than 3/4″ or engineered floors.

For all of the above reasons, the meters with a 3/4″ measuring depth are not suited for engineered floors. Dual-depth meters work well for engineered floors and also for wood floors less than 3/4″ including all types of bamboo floors. The meter can be set for the species of the wear layer and the 1/4″ depth setting allows measuring the wear layer with little or no influence from the inner core. If any installed floor is measured, then the user can be sure that whatever material is underneath the floor planks is not influencing the measured moisture values.