Shrinking, warping, twisting are caused by changes in moisture.

How much or how little a piece of wood is shrinking and warping, depends on its moisture content, the wood species, and the orientation of growth rings. One fact is true under all conditions: when the moisture content of wood does not change, there is no shrinking or warping. Learn more about when is wood stable.

Differences in Shrinking and Warping Between Wood Species

Some species such as Oak, Beech and Hickory shrink more than Teak, Mesquite and Cedar. To find the shrinkage factors for different wood species, check the Internet and type: “Shrinkage Factor … ” (followed by the wood species). Different percentages are listed depending on radial and tangential shrinkage.

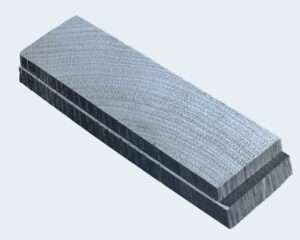

This section of a White Oak board was only 5″ wide, but as a flat grain board it shrank a lot.

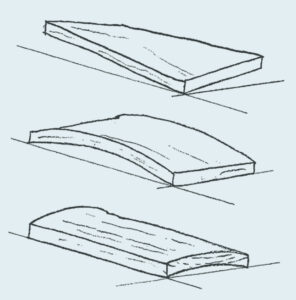

What makes wood so special is that every board has a unique design made by its growth rings. However, the varying orientations of the growth rings cause wood to shrink warp and twist unpredictably – often to the dismay of the woodworker, cabinet maker or floor installer.

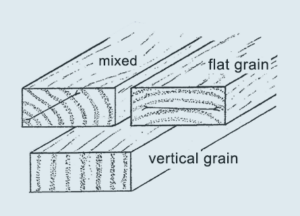

Growth Rings Determine how a Board Shrinks and Warps

Each board moves differently and, in most cases, unpredictably. The orientation of the growth rings determines the amount and direction of shrinking. However, boards with similar wood grain exhibit similar tendencies for shrinking and warping.

Most shrinkage occurs in the direction of the growth rings – flat grain (white oak sample shown right). Minimal shrinkage occurs across the growth rings – vertical grain or quarter-sawn. Typically, boards have mixed grain.

Most shrinkage occurs in the direction of the growth rings – flat grain (white oak sample shown right). Minimal shrinkage occurs across the growth rings – vertical grain or quarter-sawn. Typically, boards have mixed grain.

The different shrinkage factors within a board cause warping by pulling the edges and sides in different directions. Cupping, crowning, bowing, bending and twisting can occur, or a combination of all five.

Old Growth versus New Growth

Most lumber available today is second growth, sourced from smaller, younger trees. Old growth lumber characteristically has tighter, more evenly spaced growth rings, making it more stable. In contrast, second growth lumber has wider spaces between the growth rings, behaves more like a sponge, absorbing and loosing moisture faster. This means that, in case of a change in wood moisture content, shrinking and warping occur more quickly, then in a product built with old growth lumber.

This is one reason why now more people working with wood are using moisture meters to prevent problems such as loose joints, cupped floors, cracked tabletops, foggy finishes.

Perfect Boards

Only a few quarter-sawn boards with vertical grain can be cut from a tree.

Vertical grain or quarter-sawn boards have straight growth rings parallel to their edges. When changes in moisture content occur, these boards swell and shrink the least but do not warp.

Even if trees grew perfectly straight, only a small number of quarter-sawn boards is cut from a tree, making them rare and expensive. But they are very stable.

You may not even like the quarter-sawn boards with parallel grain and think the boards look boring. Whereas, boards with twisted growth ring patterns, knots and other blemishes look more interesting to you.

Key Factors for Drying Lumber

The first critical moisture content in the drying process is the fiber saturation point, which occurs at 25-30%. Below this point, the water within the cell walls evaporates, and the wood begins to shrink. Drying defects can occur. Above fiber saturation there is not a lot of movement, as long as no part of the boards fall below the Finer Saturation Point of 25-30% moisture content

The most careful drying process cannot eliminate these “natural” deformations. Therefore, once lumber is dry, it has to go through the planer to become a flat board. If no further changes in moisture content occur, the board will remain flat.

Moisture content, relative humidity (wet bulb) and temperature (dry bulb) are the critical factors determining a successful drying operation. See calculator for RH, T, Wet-Dry Bulb.

Uneven Absorption and Loss of Moisture in Wood

All deformations are more severe when only part of the board changes its moisture content. For instance, if floor planks are not sufficiently dry at the time of installation, the part of the boards facing the room will dry out faster than the underside facing the subfloor, resulting in cupping. For more information, see “The Challenge of Hardwood Floors.”

A similar situation occurs when a not-so-dry board is left overnight on a workbench. During the night, the side facing the air dries out and shrinks, while the side facing the workbench does not. As a result, the board can cup and may move like a teeter-totter. Even after both sides the board are dry, it may not be completely flat and could need to be planed again.

Can Shrinking and Warping Minimized?

To minimize shrinking and warping in finished wood products, use only dry lumber between 6 to 9% and maintain an environment of 35-50% relative humidity. If you live in either very moist or very dry climate zones, measure moisture in well acclimated wood and match that moisture content when selecting lumber for your next project. See EMC Chart.

Additionally, woodworkers can select boards and assemble projects by placing boards with reverse growth rings adjacent to one another to counteract the shrinking tendency of the boards. For more information, see “Helpful Hints.”