Wood is an ideal raw material: long lasting, sturdy, easy to shape, join together or glue and is continuously renewed. Above all, wood is beautiful. Everybody appreciates its durability, texture, appearance, touch, color, and unique design. However, this beauty can be short-lived when common moisture problems in wood occur.

Wood is used in many different applications – from structural building components to hardwood flooring, from furniture to children’s toys, and from cabinets to musical instruments.

The challenge of woodworking begins with choosing the right wood. If the wood is not suitable for the application, the best tools and excellence in workmanship cannot guarantee a high-quality product. Wood species, grade and moisture content determine quality and usefulness of the wood.

Common Moisture Problems in Wood

A chair with loose joints or a cabinet door that will not close, a butcher-block table with a large crack down the middle, or a veneered surface that shows surface checks. Edge banding applications where the glue line fails, a jewelry box with crooked joints, bent out of shape, and cupped floors, foggy finishes, etc.

During air and kiln drying, moisture defects such as case hardening, honeycombing, split ends or surface checks can occur. If wood is not properly stress-relieved, internal stress within the board can be suddenly released when a board is cut.

Moisture defects are irreversible. Immense stress within the wood permanently deforms or destroys the structure of the wood (cracking, checking, warping, honeycombing).

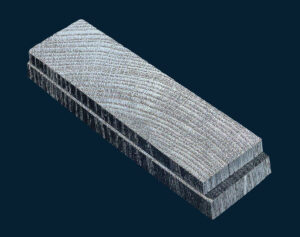

White Oak Shrinkage: 18% to 8% Wood Moisture

The flat-sawn board of white oak, with the grain parallel to its edge, shrank substantially when drying from 18% to 8%.

At the beginning of the test, both pieces ( 1 1/4” x 4”) had the same size and the same moisture content of 18%. The upper piece dried down to 8%, while the moisture level in the lower piece stayed at 18%. Placing them on top of each other makes the size difference clearly visible.

Why Moisture Problems Occur

Wood is not a homogeneous material; its structure consists of year rings that form a series of more or less concentric cylinders. These cylinders consist of irregular tubes that transport nutrients and support the tree.

Interaction with Air: When wood absorbs or looses moisture below the Fiber Saturation Point (28%-35%), the tubes expand or contract, causing the wood to swell or shrink. To the woodworker’s dismay, shrinking and swelling is often accompanied by warping. Shrinking does not occur lengthwise along the tubes.

Canges in wood moisture content occur until an equilibrium with the surrounding air is reached. At that point, the equilibrium moisture content (EMC) of the air equals the wood’s moisture content (MC). If you place wood pieces with different moisture contents in a constant climate of 70°F and 35% relative humidity for a long time, the wood will eventually reach a moisture content of 7%, regardless of species or initial moisture content.

Since 70°F and 35% – 45% relative humidity represent normal in-home conditions, hardwood floors and furniture built with a moisture content of 6-8% are stable and will remain beautiful for years.

Change in Moisture Content Causes the Most Common Moisture Problems in Wood

Wood dimensions change only when the moisture content changes. This happens mostly when the moisture falls below the fiber saturation point at about 25%. Then, some wood species change very little, others shrink and warp considerably. The amount of change depends on wood species and moisture content.

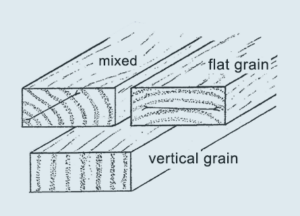

Shrinkage: Whenever wood below Fiber Saturation Point looses moisture, it shrinks. However, shrinking is not uniformly the same in all directions. It differs with the grain. Tangential shrinkage along the year rings is twice as much as radial shrinkage across the year rings. The different shrinkage factors within the same board cause warping by pulling the board in different directions.

Mixed grain: Arrows indicate radial shrinkage.

Flat grain: Arrows indicate tangential shrinkage.

Quarter sawn board with vertical grain parallel to the edges.

Year Rings: Each board has a unique year ring pattern (grain), dependent upon its position in the log. Shrinkage and warpage vary with wood moisture and with the arrangement of year rings.

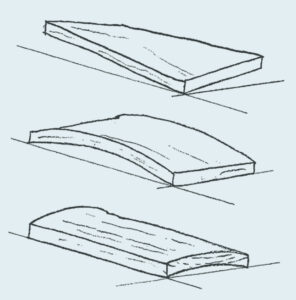

Warping: In most cases shrinking is accompanied by warping. Warping deforms boards by bowing, cupping, crowning, twisting, buckling and swelling. Surface checks and cracks also occur when the moisture content changes. In most cases a combination of all of them will occur.

Changes in moisture content cause Shrinking, warping, twisting.

Twisting: Curved diagonally across the board.

Bowing: Curved along the length of the board.

Cupping: Curved downwards along the width of the board.

Crowning: Curved upwards along the width of the board. The drawings above indicate the main deformations of a board.

The only way to avoid any of this, is to make sure the moisture content does not change.